Hunan Jingtan Automation Equipment Co., Ltd. was founded in 2021, the production base Zhuzhou Guangjichang

Technology Co., Ltd. was founded in 2014, is a high-tech enterprise

integrating research and development, production, sales and

service, and has become a famous leading manufacturer of thermal

equipment in China.Now it has two factories,which covers 3500m2.

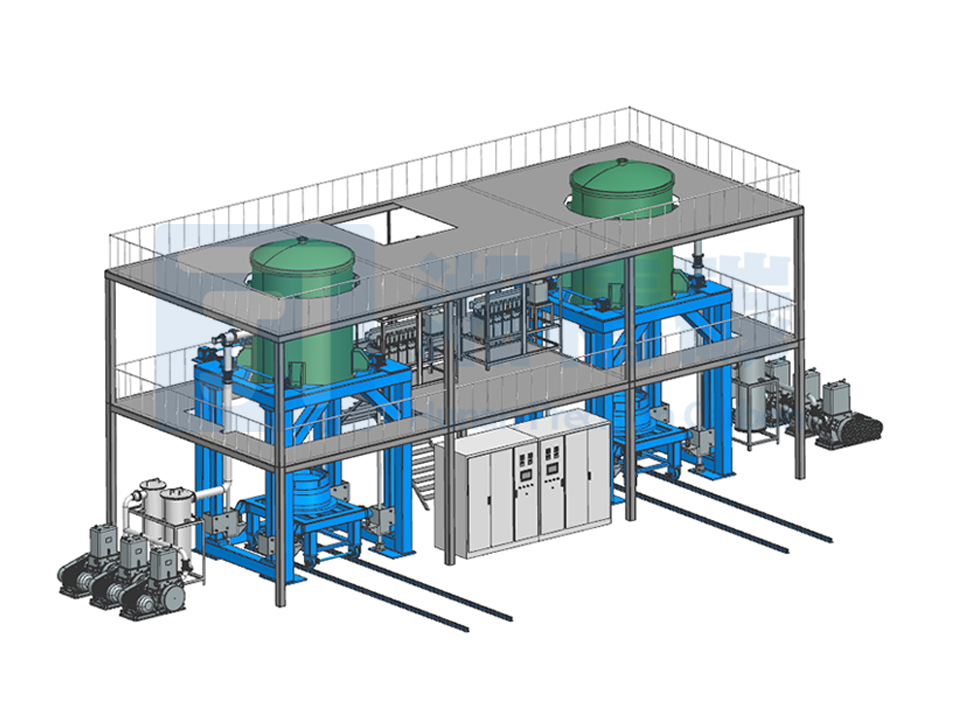

The main products are vacuum sintering furnace, silicon carbide

sintering furnace, high temperature graphitization furnace, vapor

deposition furnace, high temperature carbon tube furnace, vacuum

carbonization furnace, vacuum hot press furnace, vacuum induction

melting furnace, etc. The equipment produced by our company is

widely used in aerospace, electronics, transportation, machinery,

metallurgy, cemented carbide, refractory metal, special ceramics,

carbon carbon composite materials, semiconductor materials and

solar cells and other dozens of processing and manufacturing

industries and fields, and has won the trust and praise of the

majority of users with high-quality products and perfect service.

We have always adhered to the science and

technology enterprise, continuous innovation, pay attention to

cooperation with scientific research institutions and major

universities, and develop a number of high-tech thermal equipment

with the industry's leading level. Our company can design and

manufacture non-standard thermal equipment according to user

requirements, and provide customers with corresponding process

technical support, so as to relieve all worries for users.

The company has a number of utility model patent

certification, and has ISO9001:2015 quality management certificate,

can provide CE, UL and other product certificates for the

equipment. In order to continuously meet customer needs, to provide

"directional application, focus on development, Customized per

customer’s requirements" efficient characteristic services. Our

company has a number of domestic first cases, such as: chlorine gas

sintering furnace (can make the product purity of 99.9999%),

ultra-high temperature graphitization furnace temperature up to

3200 degrees, vacuum hot press furnace weight up to 800 tons.

"Customer first, the pursuit of quality, continuous

innovation, continue to lead!" It is the service purpose of Jingtan

company;" Based in Zhuzhou, radiating China, facing the world "is

our company's service concept. At present, our products are mainly

exported to Europe, Middle East, Southeast Asia and other

countries; in the domestic market has also won the praise of the

majority of users, has been highly recognized by the industry.

Hunan Jingtan Automation Equipment Co., Ltd. strives to become your

most trusted manufacturer of high temperature equipment.